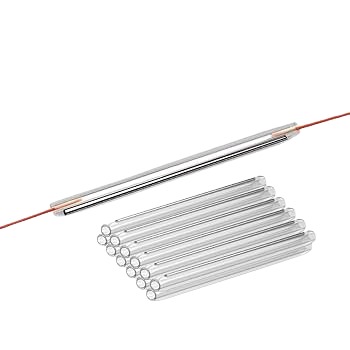

FO Heat Shrink

Cornet Fiber Optic Heat Shrink Sleeves

used in protecting fusion splices

KEY FEATURES

•Protects fusion splice joints from moisture, bending, and mechanical damage

•Transparent tubing allows easy inspection of the splice alignment

•Inner hot melt adhesive layer bonds tightly to the fiber and coating

•Stainless steel rod inside adds strength and anti-bending support

•Shrinks quickly under heat (using fiber oven) without air bubbles

| Parameter | Specification |

| Type | Fiber optic fusion splice protection sleeve |

| Outer Tube Material | Polyolefin (heat shrinkable) |

| Inner Layer | Hot melt adhesive (EVA or similar) |

| Reinforcing Rod | Stainless steel (1 rod, 1.0 mm) |

| Operating Temperature | -45°C to +100°C |

| Shrink Temperature | Starts at ~90°C; full shrink ~120–140°C |

| Shrink Ratio | 2:1 |

| Lengths Available | 60 mm |

| Outer Diameter (pre-shrink) | ~3.0 mm ±0.2 mm |

| Outer Diameter (post-shrink) | ~1.2 mm ±0.1 mm |

| Color | Transparent |

| Durability | Waterproof, UV resistant, corrosion-proof |

| Packaging | 100 per bag |

| Part NO: |

| CN-FO-HS-100 |